Full-Spectrum

Metal Additive Manufacturing

Our services span the entire additive manufacturing workflow—from DfAM to precision finishing. Whether you need a single prototype or scaled production, Howco delivers precision metal components that perform in extreme environments.

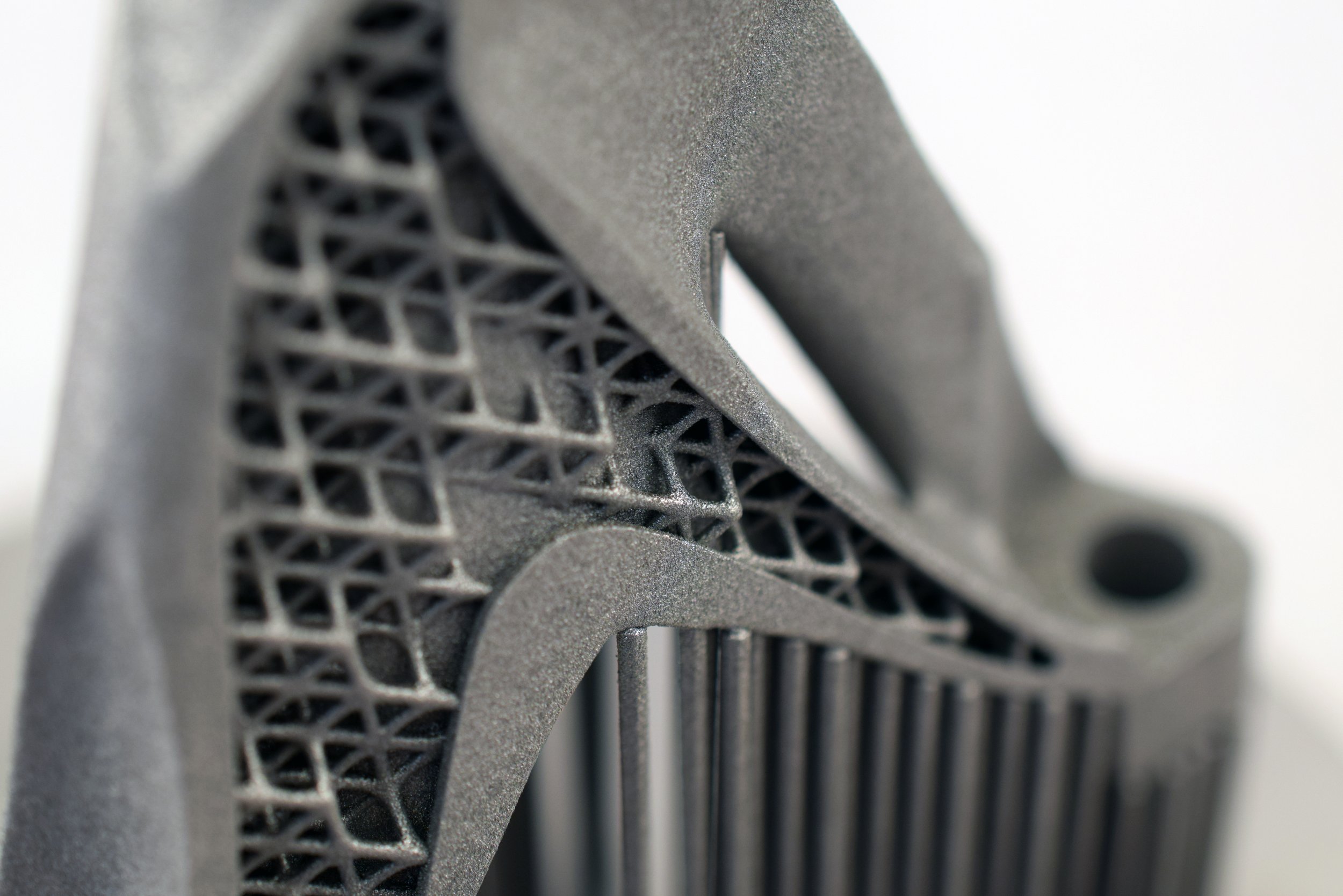

Design for Additive Manufacturing (DfAM)

We help engineers take full advantage of additive design freedom through design optimization, best practices, lattice structures, and part consolidation.

By removing unnecessary mass and minimizing supports, our design team improves performance, reduces weight, and shortens build time—without compromising mechanical integrity.

Laser Powder Bed Fusion (L-PBF)

Our multi-laser L-PBF systems build dense, high-strength components with exceptional repeatability.

Layer by layer, a precision laser melts metal powder to create parts with geometries unattainable by conventional machining.

This process allows rapid iteration, reduced waste, and lightweight, high-performance designs.

Materials: Inconel 718, Inconel 625, Titanium Ti-6Al-4V, C103 Niobium, and Stainless Steel 316L.

Build Volumes: 280 × 280 × 365 mm & 500 x 280 x 365 mm.

Heat Treatment & Finishing

Our workflow integrates heat treatment, HIP, and precision machining to deliver optimal mechanical properties and part integrity.

Howco Additive operates a 2-bar vacuum furnace and 5-axis machining on-site, providing in-house control when projects require custom heat cycles and post-machining. For certain materials and specifications, we also work with certified aerospace facilities to guarantee metallurgical consistency. Each component undergoes final inspection and full documentation before release.

Inspection & Verification

From powder traceability to dimensional accuracy, our parts meet rigorous aerospace, defense, and energy standards.

We employ CMM inspection, 3D scanning, and tensile testing to validate builds based on customer specifications.

AS9100 and ISO9001 certified and ITAR Registered