Expertise Across Environments

Built for downhole, orbit, and everything in between.

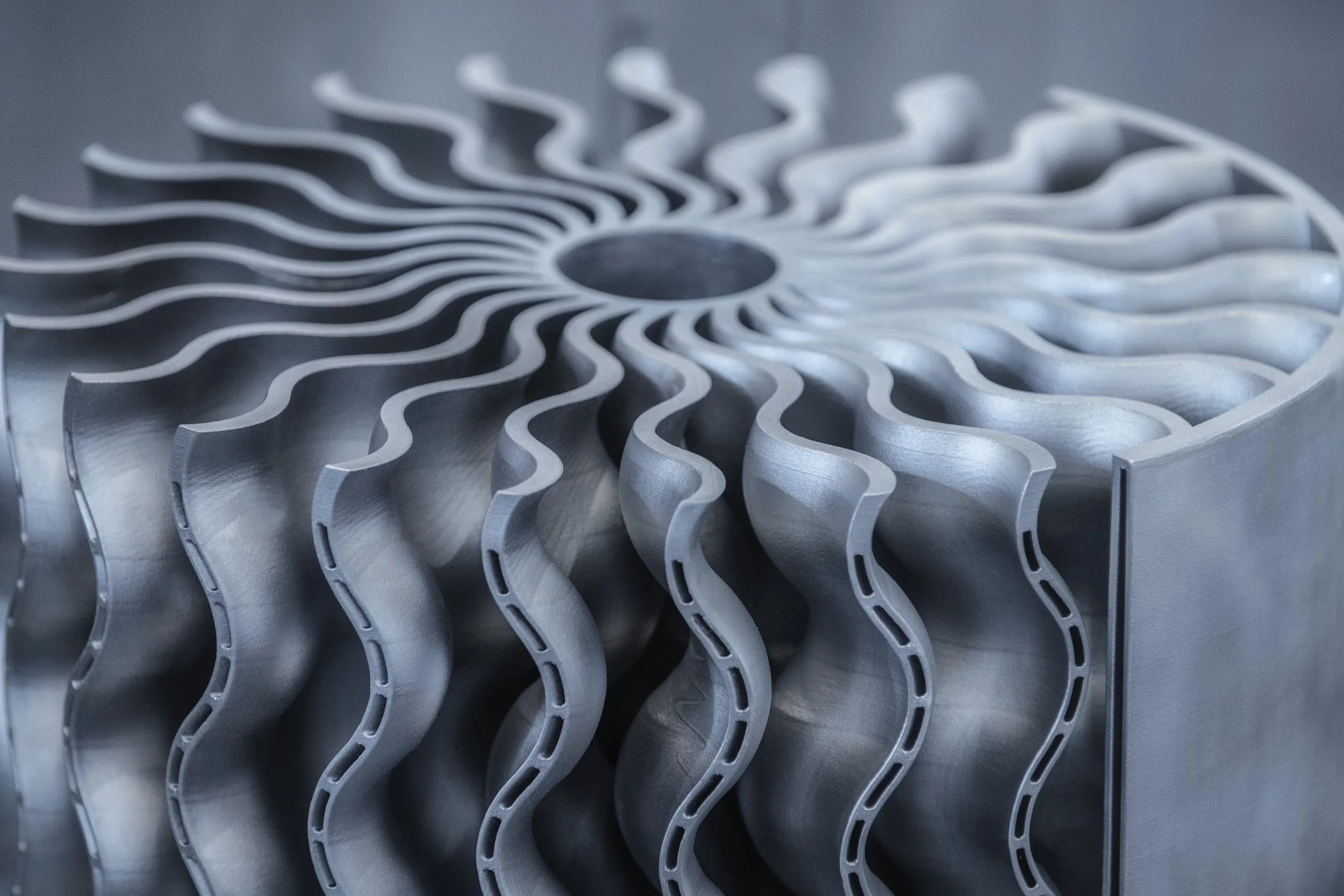

Aerospace

Additive manufacturing enables lightweight, complex geometries that reduce fuel consumption and assembly time. Howco produces flight hardware, brackets, heat exchangers, and propulsion components from Inconel 718 and Titanium Ti-6Al-4V, balancing strength with weight savings.

Oil & Gas

From corrosion-resistant downhole tools to high-performance manifolds and pressure components, our additive manufacturing process delivers durable parts designed to withstand extreme environments.

Materials like Inconel 718, Inconel 625, and 316 Stainless Steel offer proven strength, oxidation resistance, and excellent corrosion protection — making them ideal for demanding applications in energy, aerospace, and marine sectors.

Mission Critical

We deliver mission-ready components with strict ITAR compliance. Additive manufacturing shortens development cycles and allows rapid redesigns without tooling—perfect for low-volume, high-complexity defense hardware.

Space

Using high-temperature alloys like C103 Niobium, we manufacture lightweight, high-stiffness parts for rocket engines and satellite systems where performance is critical beyond Earth’s atmosphere.

Industrial Prototyping

Accelerate your innovation pipeline with fast-turn metal prototypes. Validate form, fit, and function within days—no tooling required.