From Powder to Performance: Inside Howco’s Metal AM Process

Metal additive manufacturing isn’t just a machine operation — it’s an engineered, end-to-end process. At Howco Additive, delivering parts that meet spec in demanding environments (like oil & gas, aerospace, or defense) requires tight control across three integrated phases: material input, process execution, and qualified output.

Here’s how we build trust into every layer.

Phase 1: Controlled Input — Material, Data, and Setup

Before a single layer is fused, the foundation is laid with rigorous controls on material selection, build prep, and traceability.

Material control

We use aerospace-grade virgin powder with tight specifications on chemistry (AMS 7002 or equivalent), PSD (typically 15–45 μm), and morphology. For alloys like Inconel 718, Inconel 625, Titanium, and 316L, powder lot traceability and handling procedures are enforced to prevent contamination and maintain flowability. All powders are stored in inert environments and sieved before loading to ensure consistency.Build setup and part orientation

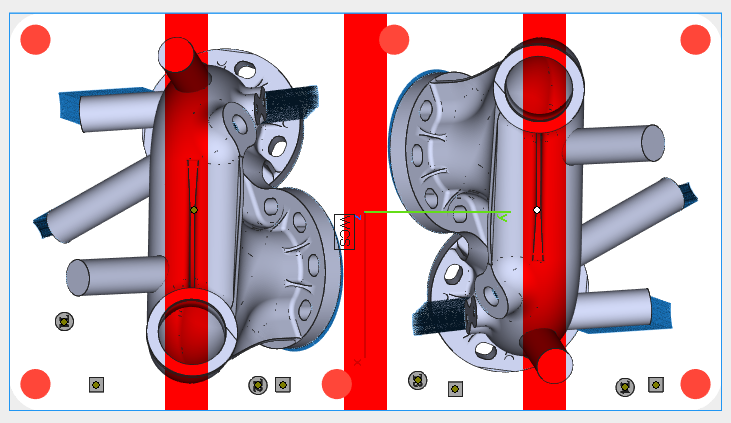

Using advanced software (e.g. Materialise Magics, 3DXPert), we design support strategies and scan vectors that minimize residual stress, distortion, and thermal accumulation. Orientation isn’t just about “fitting” the part — it’s about controlling thermal gradients, gas flow, and recoater interactions. Key surfaces and datums are planned with downstream inspection and machining in mind.Qualification control

For qualified programs, we use locked build files tied to controlled parameter sets. Our machines are calibrated and verified prior to each run, and build logs are generated for complete digital traceability — including inert gas purity, chamber pressure, and laser data.

Phase 2: Precision Execution — Build, Monitoring, and Data Capture

This is where the part begins to take shape — but execution isn't left to chance.

Laser powder bed fusion (L-PBF)

Our production is anchored by multi-laser, high-stability L-PBF systems. These machines operate under tightly controlled atmospheres (O₂ < 100 ppm) and inert gas flow to maintain consistent thermal profiles. Laser power, speed, hatch spacing, and layer thickness (typically 30 or 60 μm) are validated for each alloy.Build removal and handling

Post-print, the plate is removed in a controlled environment. Loose powder is recovered and sealed for requalification or disposal per internal standards. The part is then removed using controlled fixturing to avoid damage or residual stress.

Phase 3: Qualified Output — Post-Processing and Final Verification

Even a flawless build is just a halfway point. The final properties are locked in through proven post-processing.

Heat treatment and HIP

We apply specification-driven thermal cycles (e.g. AMS 2774, ASTM F3055, customer-specific specs) using vacuum furnaces and HIP systems operated by certified U.S. partners. These steps eliminate internal porosity and achieve desired mechanical properties — typically 120-150 ksi MYS for Inconel 718 and ~ 80 ksi for Ti-6Al-4V.Machining and finishing

Precision surfaces are machined to drawing spec using CNC machining. We design parts with stock allowances and datum control to ensure alignment between as-printed and as-machined features. Threads, bores, and sealing surfaces are held to tight tolerances, and surface finish can be refined to meet aerospace or O&G specs.Inspection and documentation

Final inspection includes CMM dimensional reports, metallographic analysis, and mechanical testing via NADCAP or ISO 17025 labs. The result is a part delivered with full pedigree: material certs, build logs, heat treat certs, and inspection records — all tied to a unique serial number or lot code.