Proven Projects. Measurable Impact.

Explore success stories from the field, showcasing additive manufacturing at its best—precision, performance, and repeatability.

-

Preventing Oil Migration with Additive Manufacturing: Exxon Machinery Anti-Wicking Device

Howco Additive collaborated with Exxon and LSU to redesign a critical machinery anti-wicking device—preventing oil from traveling up thermocouple wires and damaging electrical cabinets. Using 316L stainless steel and Laser Powder Bed Fusion (LPBF), the team delivered a fully optimized, leak-resistant, technician-friendly design with improved sealing, serviceability, and AM-efficient geometry. The result is a cost-effective, field-ready, and additive-optimized solution that enhances reliability and protects refinery instrumentation.

-

Lightweight Titanium Control Arm for Baja Racing: 60% Weight Reduction with LPBF

Built for extreme off-road performance, this project showcases Howco Additive’s ability to replace a heavy OEM steel upper control arm with a Ti-6Al-4V, LPBF-optimized design. Using generative geometry, precision post-machining, and aerospace-grade heat treatment, the new component delivered over 60% weight savings, improved fatigue life, and tighter suspension responsiveness for a Baja-modified Ford Raptor. The result is a stronger, lighter, race-ready assembly engineered to withstand the punishment of desert racing.

-

Conformal Cooling Insert Delivers 75% Faster Cycle Times for High-Volume TPE Molding

Through advanced conformal-cooling design enabled by Nikon SLM technology, ABB transformed a high-volume injection-molding insert and cut cooling time from 30 seconds to just six. Multiple channel geometries were evaluated and optimized for LPBF, then validated through thermal simulation and real-world testing. The redesigned insert achieved a 75% reduction in total cycle time, improved temperature uniformity, and reduced scrap—demonstrating the powerful impact of additive manufacturing on tooling performance and production efficiency.

-

Topology-Optimized Titanium Gooseneck Bracket Achieves 31% Weight Reduction for Aerospace Actuation Systems

Designed for the demanding loads of Krueger flap actuation, this bracket was completely re-engineered using Nikon SLM additive manufacturing to replace a complex machined steel assembly. Through DfAM, topology optimization, and twin-laser LPBF processing, ASCO reduced mass from 2050 g to 1416 g, integrated multiple subcomponents into a single part, and cut build time nearly in half. The final Ti-6Al-4V structure meets stringent aerospace requirements while delivering meaningful weight savings and simplified assembly—demonstrating the transformative impact of metal AM on flight-critical hardware.

-

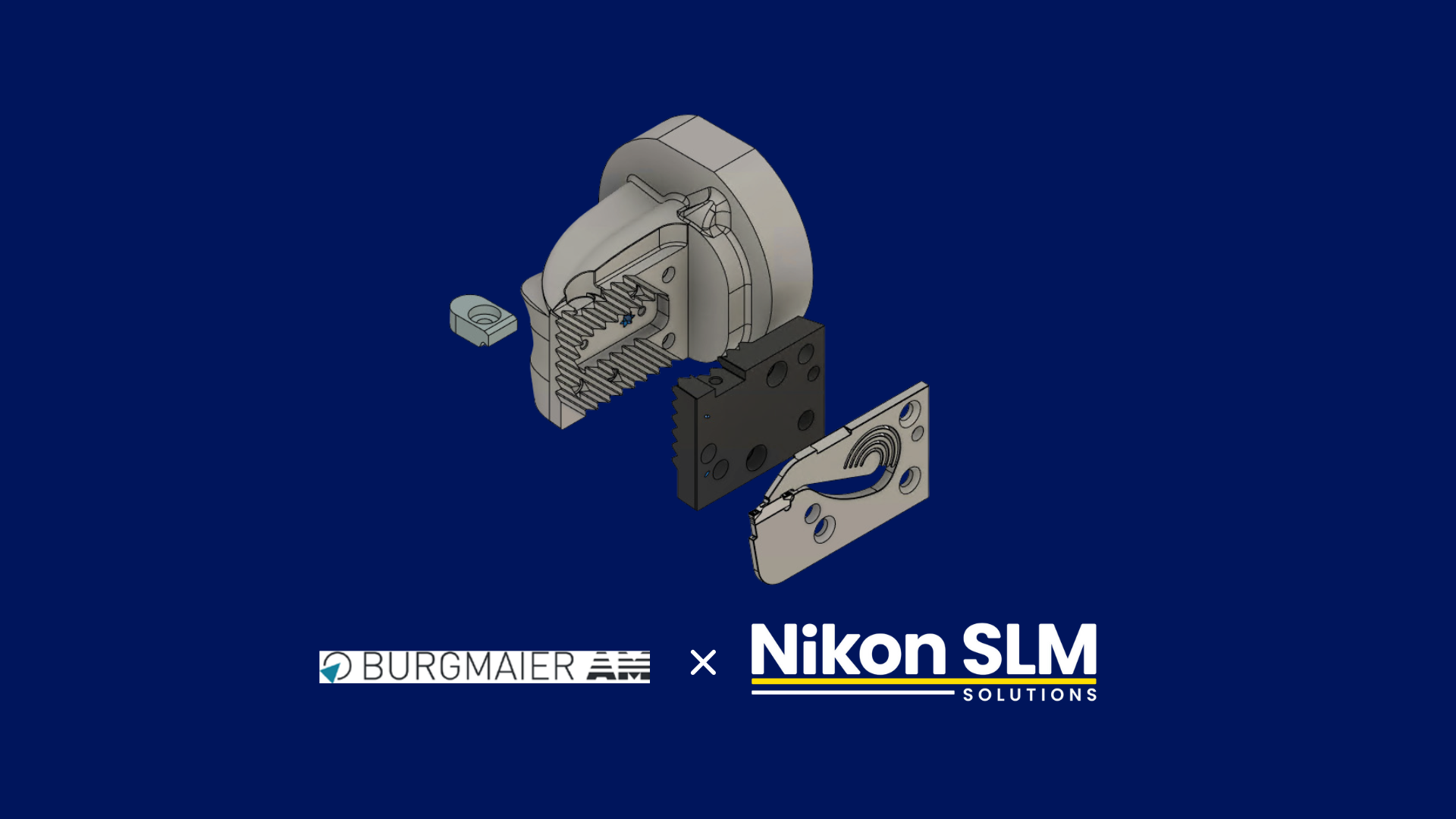

Hybrid Additive Grooving Tool Delivers 45% Weight Reduction and Superior Cooling Performance

By reengineering a conventional grooving tool with Nikon SLM additive manufacturing, Burgmaier and ZCC introduced a star-shaped conformal cooling channel and a hybrid-built holder that dramatically improves tool life and machining efficiency. The redesigned system achieves 45% weight reduction, faster and more even cooling, higher durability, and lower operating cost—while enabling modular replacement of individual components. This AM-driven approach enhances precision cutting performance and sets a new benchmark for next-generation metalworking tools.

-

Conformal-Cooled Hybrid Mold Insert Cuts Cycle Time by 44% for High-Precision Injection Molding

Omni Mold solved a persistent hotspot problem by redesigning a mold core insert with Nikon SLM’s additive manufacturing technology, replacing a conventional spiral channel with a fully conformal cooling path. Using a hybrid AM approach, they achieved 88.75% faster print time, uniform cooling, and a cycle-time reduction from 45 to 25 seconds—all while improving part quality and lowering production costs. The result is a highly efficient, precision-engineered mold insert that showcases the impact of AM-driven cooling optimization.

-

Lightweight Multifunctional Wing Segment Demonstrator Advances AM in Aerospace Structures

Pushing the boundaries of airframe design, RWTH Aachen’s SLA institute partnered with Nikon SLM Solutions to create an additively manufactured wing-tip segment built around complex lattice structures and a single-piece design philosophy. Produced in AlSi10Mg on the SLM®500, the demonstrator delivers high structural efficiency, reduced mass, and modular integration while meeting strict accuracy requirements for future certification. This project marks a meaningful step toward next-generation, eco-efficient aircraft components enabled by advanced metal AM.

-

Additively Manufactured Rocket Engine Enables Record-Breaking Student Propulsion Milestone

Karman Space Programme partnered with Nikon SLM Solutions to design and build a fully reusable liquid rocket engine featuring integrated regenerative cooling channels in Inconel 718. Manufactured as a single optimized structure, the engine delivered 7.2 kN of sustained thrust across multiple hot-fire tests with zero required repairs—proving both durability and thermal efficiency. This AM-driven approach reduced complexity, cut weight, accelerated development cycles, and now powers KSP’s upcoming reusable Vega Rocket mission.

-

AM-Produced Compressor Housings Cut Lead Time and Cost in Early Automotive Development

Brose replaced traditional sand-cast compressor housing prototypes with additively manufactured parts produced on the Nikon SLM®500, enabling rapid validation of A- and B-sample components. By tailoring their own alloy and print parameters, Brose achieved material behavior comparable to die-cast parts—unlocking lead-time reductions from 20+ weeks to under two, and cost savings of roughly 80%. This adoption of AM as a sand-casting substitute streamlines early development, increases repeatability, and supports more sustainable automotive prototyping.